|

Quality Control

We take quality seriously! In terms of mechanical product quality, Echo Machinery controls raw materials, accuracy of dimensions, metallurgy, hardness, and surface condition.

Control Raw Material

Echo Machinery controls the raw material by a direct reading spectrometer when testing the molten raw materials’ chemical composition. What’s more, Echo Machinery QC also randomly uses the hand spectrometer to double inspect the products’ chemical composition.

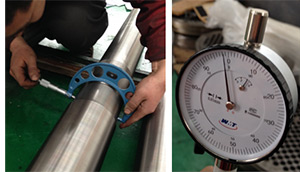

Control Accuracy of Dimensions

Echo Machinery quality control technicians will inspect each dimension during production. Once it is found that dimensions are out of tolerance, the part is returned to its last production procedure for repair. If it cannot be repaired, it will be scrapped. After a final dimension inspection, the finished products are presented to you.

Control Metallurgy and Hardness The professional method to inspect a product’s metallographic structure is using a metalloscope. A sample from the component is polished and/or etched in preparation for viewing. The right metallographic structure is the critical criterion to verify that the heat treatment has been correctly processed and whether the hardness is correct or not.

Hardness testing is an auxiliary way to test the metallographic structure. Hardness is a parameter to indicate the wearing performance of material.

Control Surface Condition

Surface condition means the surface quality. Product surfaces should be clean, painted, smooth, no defects, no sharp corners or even sand-blasted. The first impression of the products is the surface condition or appearance.

In addition to the above quality control procedures, Echo Machinery also undertakes non-destructive testing methods -- ultrasonic inspections and the magnetic powder test. The typical Charpy impact test and tensile test are also conducted during production.

|